You are here

Hot Bar Systems

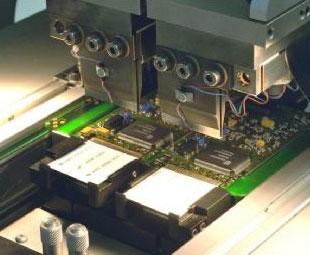

AMADA WELD TECH Hot Bar systems can be used for Hot Bar Reflow Soldering, ACF Bonding, Heat-Sealing and Heat Staking. Hot Bar systems include constant-heat or pulsed-heat process technology.

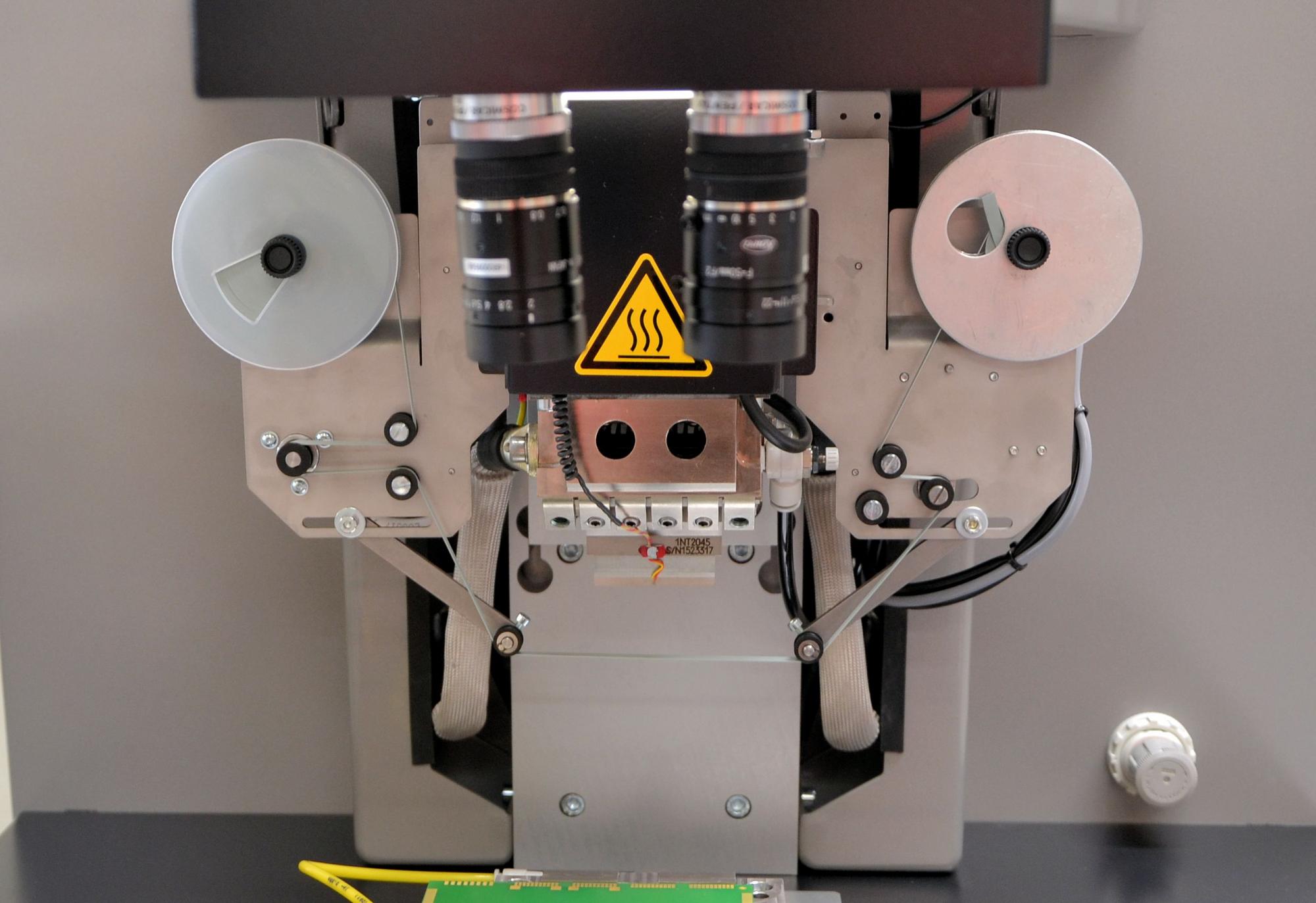

The MIYACHI EAPRO Hot Bar systems use the Thermode technology with precise temperature, force and process control at the heart of our Hot Bar system to create a robust and multi-functional platform for Hot Bar Reflow Soldering, ACF Bonding, Heat-Sealing and Heat Staking applications.

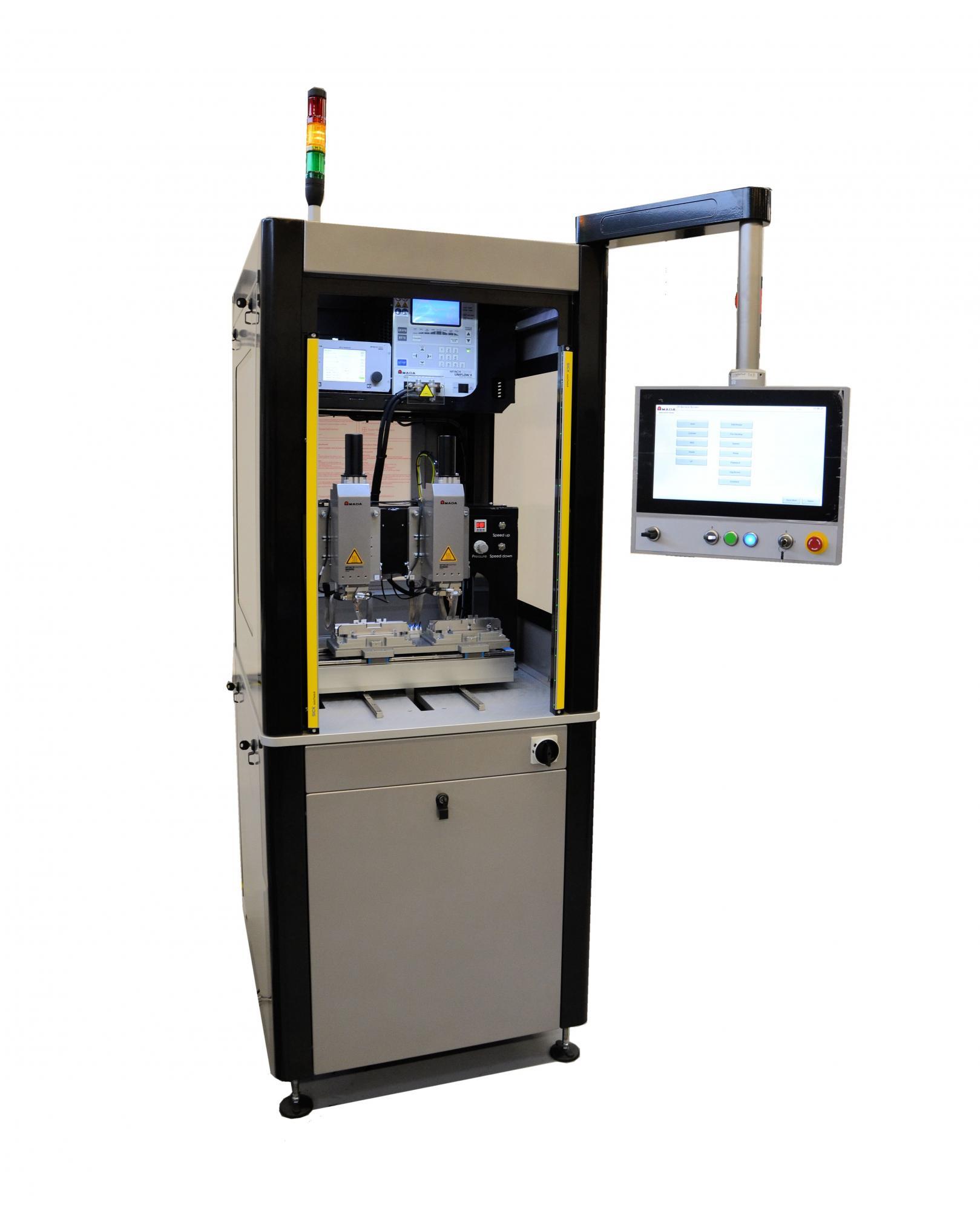

These processes are the preferred solution for Reflow Soldering thermally sensitive components such as computer chips and connectors. The same Hot Bar systems are also ideal for Heat-Sealing / ACF Bonding flexible connections between LCD and PCB components and for Heat Staking plastic modules. AMADA WELD TECH designs and manufactures a full range of automated workstations for both processes.

In addition to the range of standard systems, AMADA WELD TECH modifies equipment for existing specifications and provides customized systems to meet your specific needs.

Hot Bar System Configurations

Benefits of the Hot Bar System:

- Turn-Key deliverables

- Customized Hot Bar application solutions

- On-site system integration, qualification and training

- Applications expertise and global support

Features of the Hot Bar System:

- Process data traceability and storage

- Alignment and positioning modules

- Visual inspection systems

- Functional product-test modules

- Dispensing modules

- Parts feeding

- Product handling and positioning

- Closed loop process quality control

- Process development