You are here

Hermetic Sealing of Electronic Packages

Precision components, RF packages, optoelectronic devices and sensors that need to be resistant towards challenging environmental conditions can be sealed into metal packages. AMADA WELD TECH manufacturers the equipment to seal these metal packages by means of welding, brazing and soldering. The heat source for this process can be an electrical current or laser light. The seal can be made as a series of overlapping spots, as one or more straight or circular lines or as a full circumference in one pass.

These technologies are known in the industry as Resistance Welding, Projection Welding, Rotary Welding, Seam Sealing, Soldering and Laser Welding. AMADA WELD TECH supplies products for these processes under the MIYACHI, MIYACHI UNITEK and MIYACHI BENCHMARK brands.

Process Steps

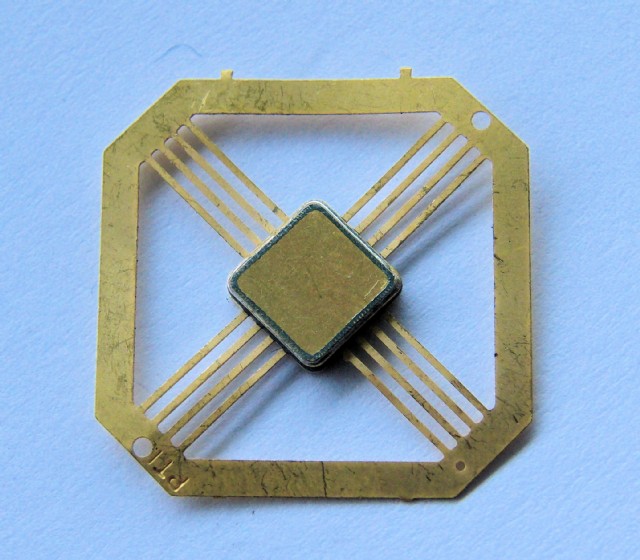

In all cases, the base of the package is positioned. At that stage, the internals are already in place or will be placed in that position. The lid will be positioned, or will be pre-positioned in a previous step. Once the lid, internals and base are in place, the internal atmosphere can be addressed. Once there is the correct internal atmosphere and the parts have been aligned and placed, , the joint can be made. AMADA WELD TECH supplies equipment for all of these process steps: out-baking, atmosphere, lid handling, lid placement, lid alignment and the final joint.

Laser Welding aluminium ultracapacitor

Heat Sources

The heat sources can be generated by passing an electrical current through the package and using the electrical resistance of the package. Concentrated light can also be directed onto the package causing the metal of the package to absorb the light and become heated.

The electrical energy and current can be as high as 10,000 Joules or 50,000 Amps and can be generated by passing a DC or AC current through the parts. The heating time is typically very short, in the range of milliseconds. The current can be “direct energy” from the mains passing in real-time though the power supply. DC currents are used for the most precise process and current control. AC currents have a longer minimal heating time (10 ms or more) and is a simpler technology. AC current can also be buffered in large capacitors (Capacitor Discharge Resistance Welding). This is typically used for larger currents. AMADA WELD TECH manufacturers and supplies all of these types of Resistance Welding power supplies.

The light energy is typically generated using a laser. The laser has a collimated beam with a single wavelength. Therefore, it can be focused onto a small spot size and a sufficient energy density can be achieved for melting metals. The laser beam is moved over the lid circumference to create a seal. The laser can be continuously switched on (CW lasers) or pulsed with pulses of a few milliseconds length. These types of lasers are Pulsed Nd-YAG lasers, Pulsed Fiber Lasers (Quasi Continuous Wave, or QCW lasers) and Continuous Wave Fiber lasers (CW Fiber lasers).

These lasers have a wavelength that is typically in the 1060 nm-1070 nm range. However, shorter wavelengths are beneficial for certain applications, as produced by the frequency doubled YAG lasers. Miyachi manufacturers and supplies all these types of lasers.

Joint Types

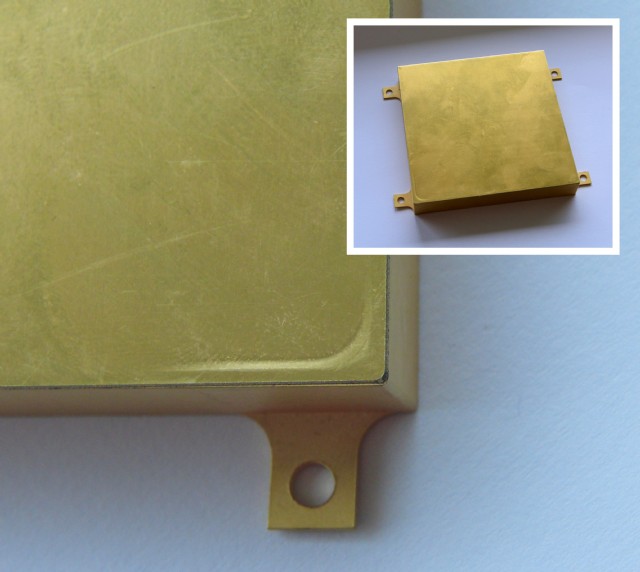

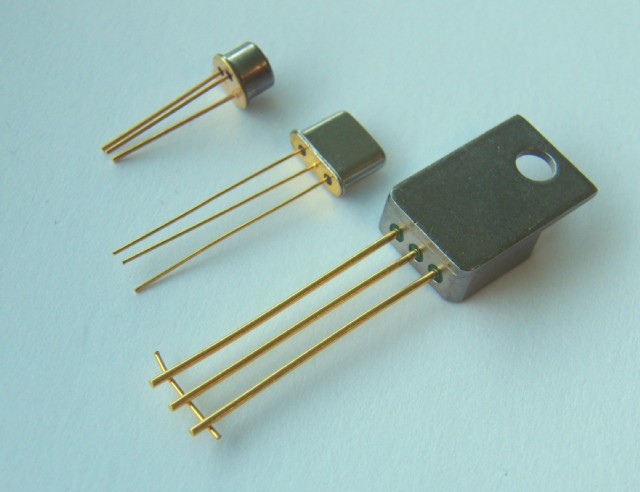

The joint is either made all at once, or in a line progressing around the circumference. This line can be a continuous line, or made up of overlapping points. Typically, smaller packages of up to 25 mm x 25 mm are joined all at once (TO-9, etc.) whereas larger packages are made with the line progressing around the package. This technology has no upper dimension limits, but most packages are below 250 mm x 250 mm

Projection welding is a joint that has a raised line. This raised line, or projection, is used for concentrating the electrical energy. It improves the joint quality and reduces the energy that is needed to make the joint.

Seam Weld on electronic package

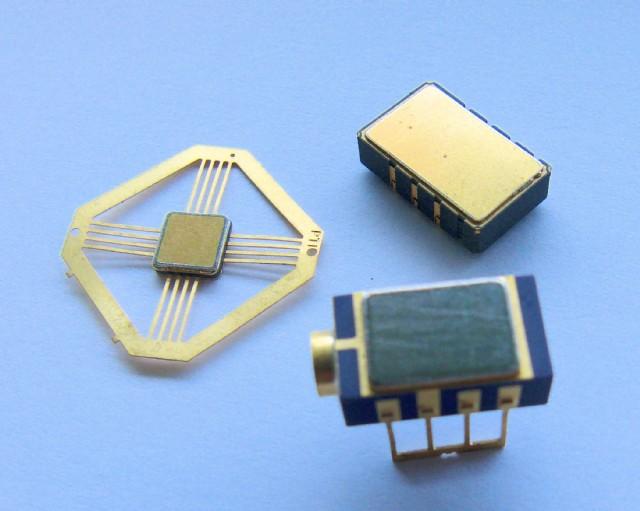

Hermetic sealing of small TO, UM and HC styles

Clamping

With Resistance Welding, the lid and the package are held with an electrode. This electrode positions the parts, feeds the electrical current to the part and pushes the parts together. The electrode may have a shape or cavity for holding the lid and base part. It may also be a wheel that rolls over the joint. In this case, the process is called Seam Sealing Electric Welding.

Laser welding is a contact-free process. This means that the parts need to be positioned and clamped together with external tooling. Typically, this tooling holds the parts in place for the laser to make a few tacks or spots around the circumference. After making these tacks and removing the tooling, the seam can be fully created.

Seam Weld on ultracap

Atmosphere inside the Package

The atmosphere in these packages can be ambient air or a dedicated atmosphere. A typical dedicated atmosphere would be argon, nitrogen, or a mixture of gases such as argon with helium as a sniffer gas for the detection of leaks afterwards.

This dedicated atmosphere can be determined before, during or after welding. A full-sized glovebox with a baking oven for drying/dehydrating/curing the parts before welding is most commonly used. During the joining, the parts can also be flushed with shielding gas. Parts can be laser welded in ambient air with a small hole or line that is intentionally left open. These parts can be placed in a small environmental chamber and receive a conditioned atmosphere in this chamber. They can get the final closing by making the last seal to close the seam and then receive the last weld spot to close a pre-drilled small venting hole, or weld a small ball into a pre-drilled small venting hole.

The pressure in such a cavity is usually normal ambient pressure (approximately one bar) but may also be lower (vacuum) or higher (pressurized packages).

Typical enclosure materials include stainless steel, kovar (a nickel-cobalt ferrous alloy) and aluminum.

Joint Process

The weld can be a pure weld (fusing the two metals together), a brazing (melting a third interposer metal which is normally present as a coating) or a soldering (melting of a third metal, which has a low melting temperature of max. 300 °C).

For more information on materials and joint processes, read the white paper:

Laser Seam Sealing of Electronic and Opto-electronic Packages

Hermetic sealing of small TO, UM and HC styles

Alignment & Automation

A passive alignment can be done in the tooling of either the parts itself, the tooling or the electrodes. An active alignment is possible with a camera system. The camera can be controlled by an operator, or have an image recognition system in which the computer automatically aligns the packages. This adds value to the system and improves operator independency and placement accuracy.

The parts will be positioned and joined with a MIYACHI EAPRO system, and a solution will be designed and implemented to feed parts to and from the system. AMADA WELD TECH provides a wide range of automation solutions produced under the MIYACHI UNITEK and MIYACHI EAPRO brands.

Applications of Hermetic Sealing

Markets and products vary from radar and anti-radar systems for defense, satellite navigation modules for aerospace and pressure sensors for automotive to sensors for electronics. Typical examples of seam sealing applications include sensors, radar components, battery housings, conductors for thin film cells, pacemaker cases and insulin pump cases.