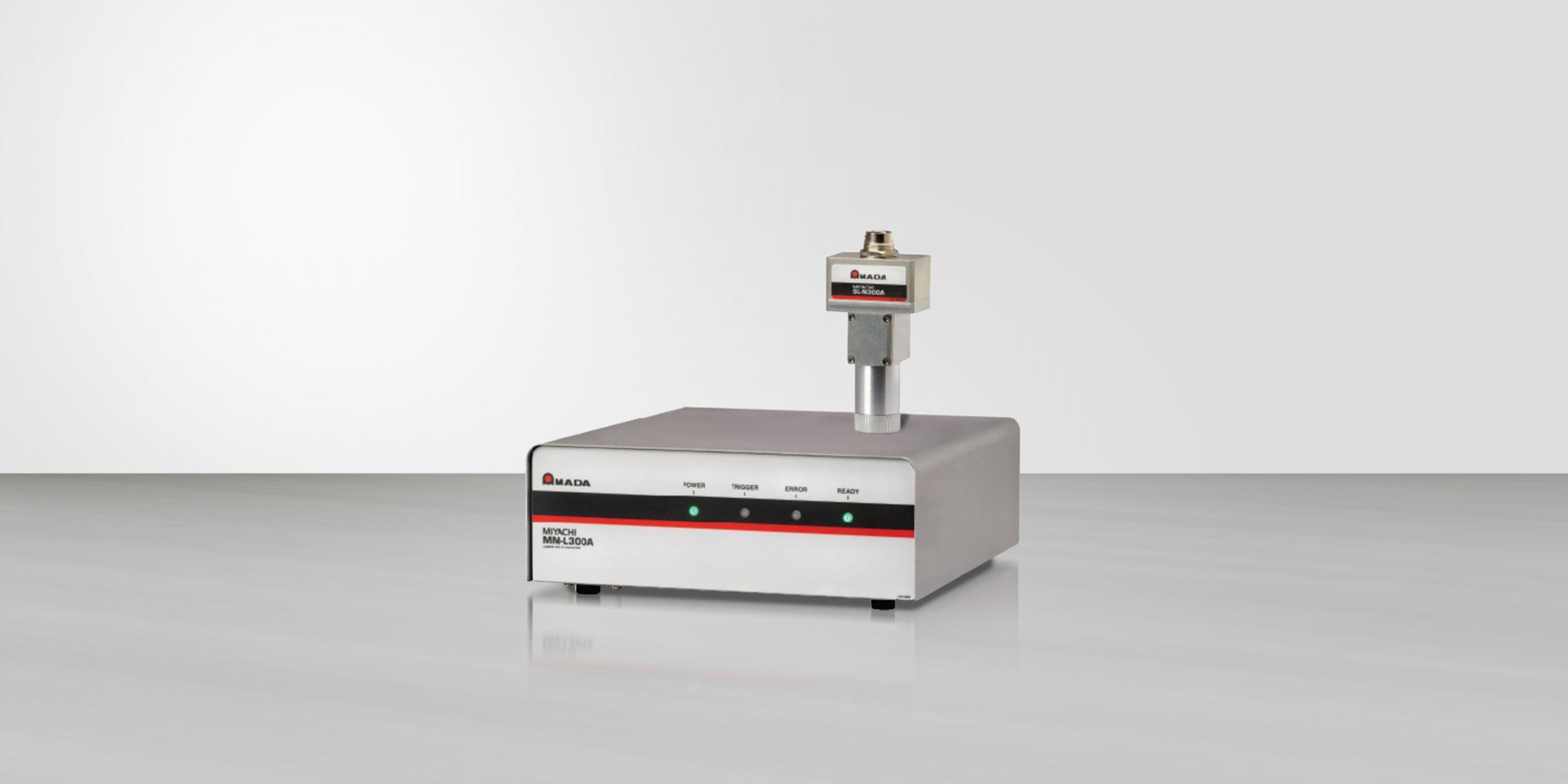

The MM-L300A laser weld monitor helps to ensure weld quality and maintain high throughput by providing realtime feedback during the laser welding process to ensure weld success. MM-L300A works by detecting and recording a thermal signal from the area of laser interaction during the welding process. The SU-N300A thermal sensor samples the signal and provides an output waveform around which envelope limits can be set.