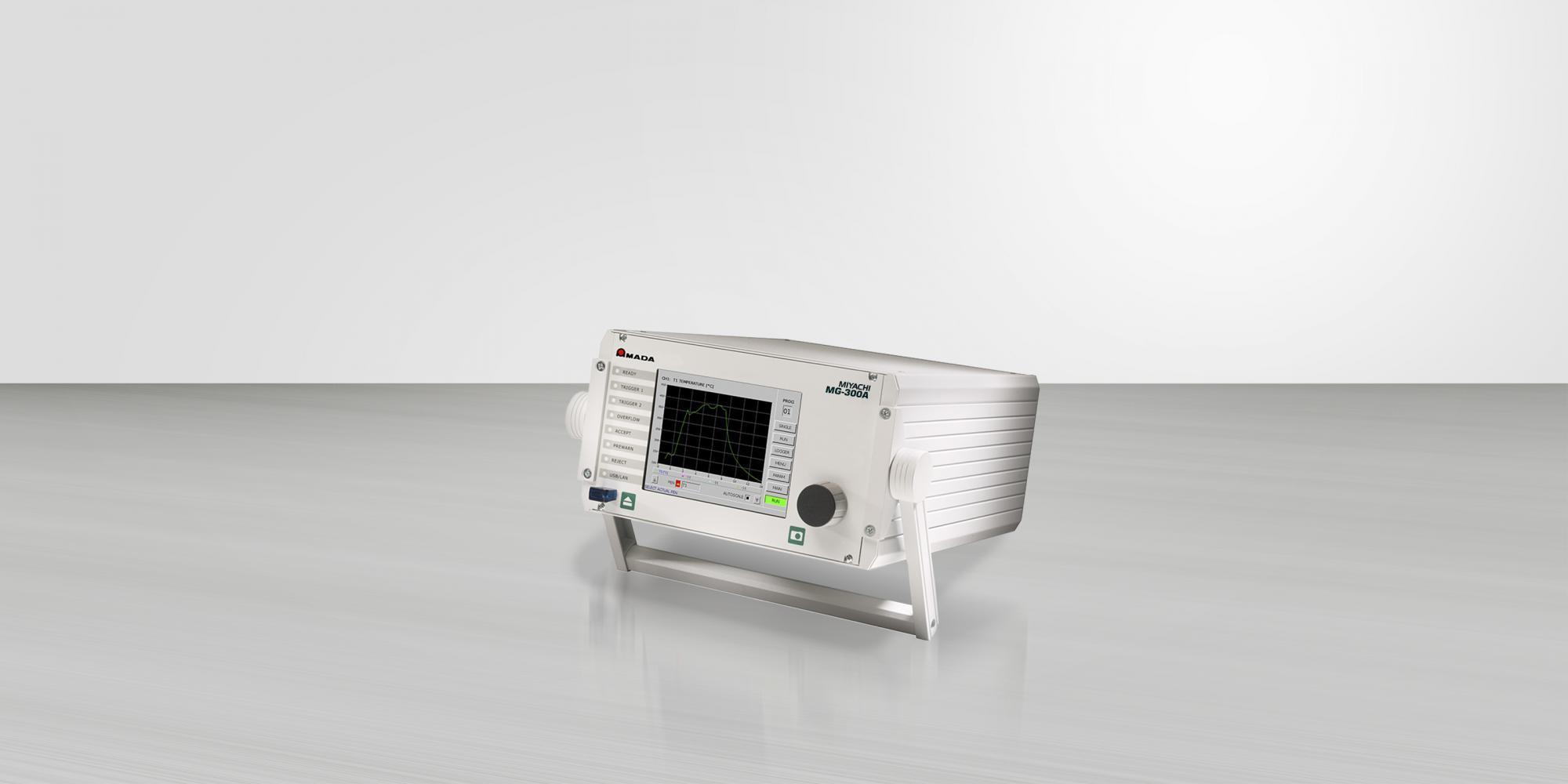

The MG-300A Digital Weld Monitor for Resistance Spot Weldingis available in three versions: Digital Basic, Digital-W1 and Digital-W2. MG3 Digital Basic monitors weld current and voltage and calculates its derived parameters w/dual channel capabilities. While the Digital-W1 version can be equipped with one the Digital-W2 version can be equipped with two displacement measuring sensors.

You are here

Advanced Process Monitoring

Reliable resistance welding requires being able to control the energy and force. AMADA WELD TECH offers various welding monitoring and testing devices which enable users to control monitoring criteria, such as the welding current, welding voltage, electrode penetration and electrode force

The WM-200A high resolution, high speed networked resistance weld monitor is designed to closely monitor the welding process, and capture, store, and send critical weld data to an on-premise or remotely located central server, enabling multiple users to view and analyze data

from anywhere in the world in real time.

With an ever-increasing emphasis on accountability, AMADA WELD TECH’s new WM-R100A Advanced Data Analysis Monitor for Resistance Spot Welding is the most advanced resistance welding monitor available from any manufacturer. It provides more of the information you need for developing resistance welding processes, production monitoring and data to support your ISO, and GMP and TQM requirements.

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.