You are here

MEA-100B - AC Resistance Welding Power Supply

The MEA-100B - AC Resistance Welding Power Supply is perfectly suited for the precision resistance welding of small-sized components. This high performance AC resistance welding power supply capable of delivering up to 8,000 A output. It offers an intuitive user interface for easy operation, combined with a compact, desktop footprint.

Key features MEA-100B - AC Resistance Welding Power Supply

- Four weld control modes to enable single-cycle, half-cycle and multi-cycle welding

- The MEA-100B has a built-in weld monitor: upper and lower limits can be set to monitor the weld quality

- Secondary constant current control (multi-cycle welding) , offering secondary current feedback every half cycle ensures stable current flow.

- Stepper function: The stepper function increases or decreases the welding current when the weld count reaches a set value. This function is used to compensate for electrode wear or to accomodate increased temperatures within an electrode or work piece.

- Single-cycle welding: first half and second half waves may be programmed separately for small parts welding.

- Half-cycle welding: added precision with half cycle welding capability.

- Power supply voltage fluctuation compensation control, compensating current every half cycle in accordance with fluctuation of power supply voltage.

| Model | MEA-100B AC Resistance Power Supply | |

|---|---|---|

| Power requirements | Single phase, 200/220/230/240/380/400/460/480VAC +13% -20%, 50/60Hz (Voltage is selectable but factory-fixed on shipment) | |

| Max. capacity | 20kVA (10% @200VAC), 26kVA (10% @400VAC), 31kVA (10% @480VAC) | |

| Control modes | 1) Secondary constant current control 2) Power-supply voltage compensation contro | |

| Welding mode | 1) Multiple cycle, 2) Single cycle, 3) Half cycle | |

| Control speed | Half cycle | |

| Welding current accuracy | @ Secondary constant-current control (when the current is set to the maximum value) Supply voltage fluctuation Resistance load fluctuation*) } within ± 2% for a fluctuation of ± 10% Inductive load fluctuation*) *) Fluctuation from our standard load. | |

| Timer setting | @ Multiple cycle mode | @ Multiple cycle mode Initial force apply, Weld 1, Cool, Weld 2, Hold 0 – 99 cycles Upslope 1, Upslope 2, Down slope 0 – 9 cycles Pulsation 1 – 9 times |

| Timer setting range: Squeeze delay | @ Single cycle mode | Initial force apply, Hold 0 – 99 cycles, First half wave/Second half wave 0.5 cycles |

| Timer setting | @ Half cycle mode | Initial force apply, Hold 0 – 99 cycles, Half wave 0.5 cycles |

| Current setting range | @ Secondary constant current control mod | Current 1, Current 2 0.20 – 9.99kA (by 0.01kA) |

| Current setting range | @ Power-supply voltage compensation control mode | Current 1, Current 2 0.0 – 99.9% (by 0.1%) |

| Current monitoring | @ Secondary constant current control mode | Upper limit setting: +1 - +49% Lower limit setting: -1 – -49% |

| Current monitoring | @ Power-supply voltage compensation control mode | Upper limit setting: 0.01 – 9.99kA (by 0.01kA) Lower limit setting: 0.01 – 9.99kA ‘by 0.01kA) |

| Option | MB-400K Toriodal coil (required at secondary constant current control) | |

| External communication | RS-482, bi-directional communication | |

| Operating environment | Temperature: 0 – 45 degree C, Humidity: 90% or below (No condensation) | |

| Power consumption | 15W or less in stand-by | |

| Global standards | CE and CCC Certified | |

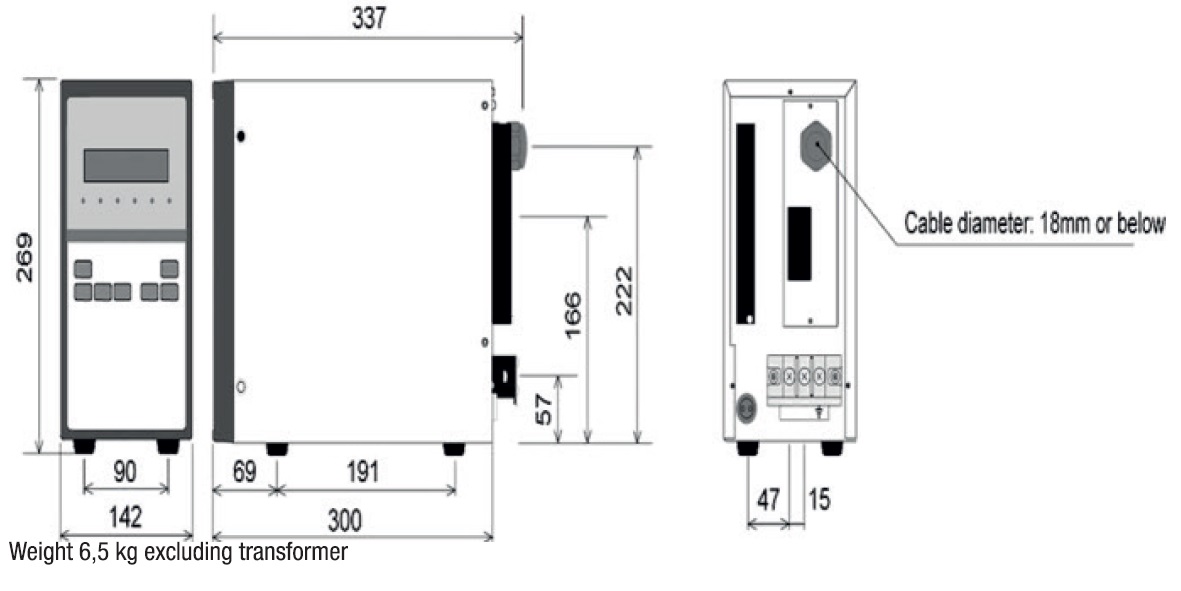

| WEIGHT & DIMENSIONS | . | |

| Dimensions (LxWxH) | 418 mm x 142 mm x 269 mm (16.4 in x 5.6 in x 10.6 in) | |

| Weight | 6.5 kg (14.3 lb) |

Documentation

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.