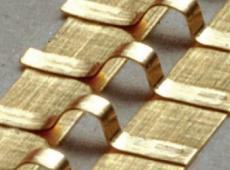

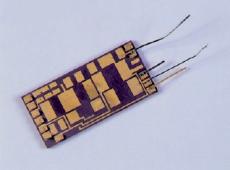

Butt welding fuses

The DC-L Family of Linear DC Resistance Welding Power Supply are high performance 1,000 Amp precision Linear DC spot welding power supplies. Both models combine an easy-to-use touch panel interface, integrated database process control and monitoring with a high accuracy, zero ripple linear transistor output stage that delivers ultra-fast 10µs dynamic process response rates, with absolute closed loop 1amp incremental accuracy and repeatability.

| Model | DC-L0600A | DC-L1000A |

|---|---|---|

| Maximum output current (A) | 1000 Amps DC | 1000 Amps DC |

| Output voltage at full load | 4V DC | 4V DC |

| Maximum output power | 4KW | 4KW |

| Full output duty cycle | 5% @600A, 3% @1,000A | 5% @ 1000A |

| Control modes | Current/Voltage/Power | Current/Voltage/Power |

| Output accuracy of setting | ±1% at Maximum Current | ±1% at Maximum Current |

| Programmed timing values | ||

| Squeeze time | 0.1 – 999.9 ms | 0.1 – 999.9 ms |

| Upslope time pulse 1 | 0.1 – 999.9 ms | 0.1 – 999.9 ms |

| Peak time pulse 1 | 0.1 – 999.9 ms | 0.1 – 999.9 ms |

| Down slope time pulse 1 | 0.1 – 999.9 ms | 0.1 – 999.9 ms |

| Delay time between pulses | 0.1 – 999.9 ms | 0.1 – 999.9 ms |

| Upslope time pulse 2 | 0.1 – 999.9 ms | 0.1 – 999.9 ms |

| Peak time pulse 2 | 0.1 – 999.9 ms | 0.1 – 999.9 ms |

| Down slope time pulse 2 | 0.1 – 999.9 ms | 0.1 – 999.9 ms |

| Hold time | 0.1 – 999.9 ms | 0.1 – 999.9 ms |

| Process monitor limits | Current/Voltage | Current/Voltage |

| No of waveforms averaged | User defined | User defined |

| Waveform window limiting range | 0 - 100% | 0 - 100% |

| Waveform window tolerances | 0 - 100% | 0 - 100% |

| Optional displacement monitoring | LVDT or Encoder Up to 6 channels of real time weld displacement monitoring | LVDT or Encoder Up to 6 channels of real time weld displacement monitoring |

| Input requirements | 1 phase | 3 phase |

| Input voltage | 95 - 265VAC | 380 - 480VAC |

| Control I/0 | Opto isolated | Opto isolated |

| Serial communications | Ethernet via TCP/IP, USB 2.0, RS232 | Ethernet via TCP/IP, USB 2.0, RS232 |

| WEIGHT & DIMENSIONS | ||

| Width | 190mm (Vertical) 400mm (Horizontal) | 190mm (Vertical) 400mm (Horizontal) |

| Height | 400mm (Vertical) 190mm (Horizontal) | 400mm (Vertical) 190mm (Horizontal) |

| Depth | 400mm (Vertical) 400mm (Horizontal) | 400mm (Vertical) 400mm (Horizontal) |

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.