You are here

FP200, FP5 - High Force Spot Welding Heads for automation

Thanks to their excellent dynamic response and their stable follow-up properties the FP-series weld heads represent the best solution for a wide range of resistance welding applications.

The FP werld head series is designed for welding of materials which require precise and reliable welds continuously.

Both weld head types deliver outstanding weld process stability and consistent reproducibility.

Maximum reliability and ease of maintenance generate an outstanding cost ownership and a very long product life in operation.

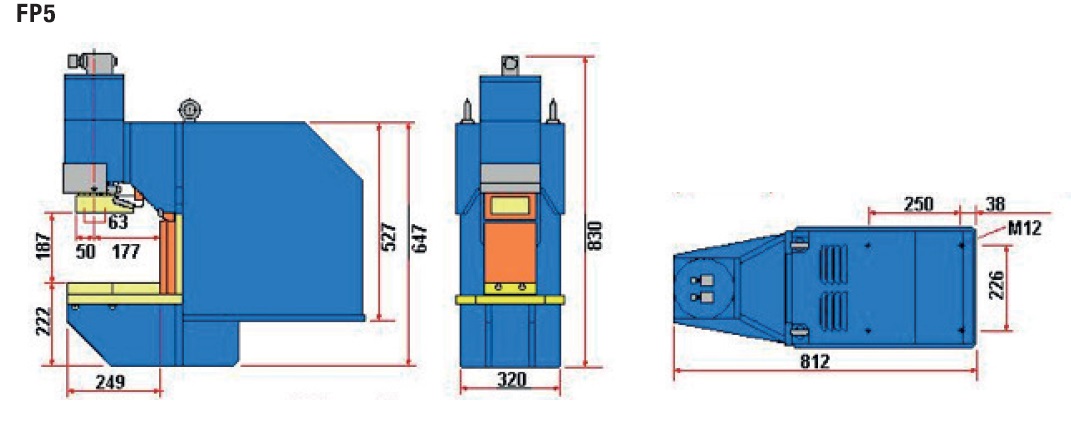

The FP-Series has two main products. The FP200 offers three (-1, -2, -3) and the FP5 (-8, -18) two options. The product differences are described in the Technical Specifications table.

Key features FP200, FP5 - High Force Spot Welding Heads for automation

- Modular for easy integration for automation

- Adjustable force-firing from 400 N to 18000 N

- Fast follow-up

- Water-cooled electrode holders

| FP-Series | FP200 | FP5 |

|---|---|---|

| Configuration | Stand design with horizontal secondary connection and water distributor | Stand design with upper and lower T-slot table |

| Options | Automatic weld head without stand, without lower electrode holder, with adapter | Upper T-slot table adjustable |

| Electrode stroke | 40 mm | 50 mm |

| Closing stroke | Pneumatic | Pneumatic |

| Weld force max | 3300 N (optionally 1000 N) | -8: 8000 N, -18: 18000 N |

| Air pressure supply | Max. 6 bar | |

| Weld force adjustment | Via adjustable pressure control valve or proportional valve | Via valve bank or proportional valve |

| Electrode shape | -1: cylindrical, d = 10 mm, -2, -3: MK1 electrodes | -1: cylindrical, d = 10 mm, -2, -3: MK1 electrodes |

| Electrode holder | -1: Water-cooled armholders with uncooled circular arms. -2: Top; Centric MK1 point type head; Bottom: MK1 electrode holder with water-cooled shaft. -3: water-cooled MK1 point-type head. | Upon request |

| Weld cables | 4x95 mm2 400 mm long | Upon request |

| Environment temp. | 0-40 °C | |

| Cooling | Water-cooled electrode holders | Water-cooled T-slot table |

| Weight | 19 kg | 300 kg |

| Dimensions (LxHxD) | Variying | 812 x 830 x 320 mm |

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.