You are here

F120-Z and F160-Z - Weld Pincers for Automation

Thanks to their floating bearing with locking cylinder and their excellent follow-up properties the F-series weld pincers are designed for a wide range of resitance welding applications. Maximum reliability and ease of maintenance generate an outstanding cost of ownership and a very long product life in operation. The weld pincer F-series is designed for welding of materials which require precise and reliable welds continuously. Both weld pincer types deliver outstanding weld process stability and consistent repoducibility.

The F120-Z and F160-Z weld pincers are designed to be used in combination with a variety of electrodes, force sensors and displacement sensors.

Key features F120-Z and F160-Z - Weld Pincers for Automation

- Modular for easy integration for automation

- Adjustable force-firing from 1.2 N to 550N

- Pneumatic actuation

- Optional horizontal mounting

- Ideal for safety critical applications

| Model | FP120-Z | FP160-Z |

|---|---|---|

| Configuration | spring types 1 to 3 for force ranges 15 to 150 N; float mounting weld pincers with quickchange system for electrodes locking cylinder | spring types 1 to 4 for force ranges 50 to 550 N; float mounting weld pincers with quickchange system for electrodes locking cylinder |

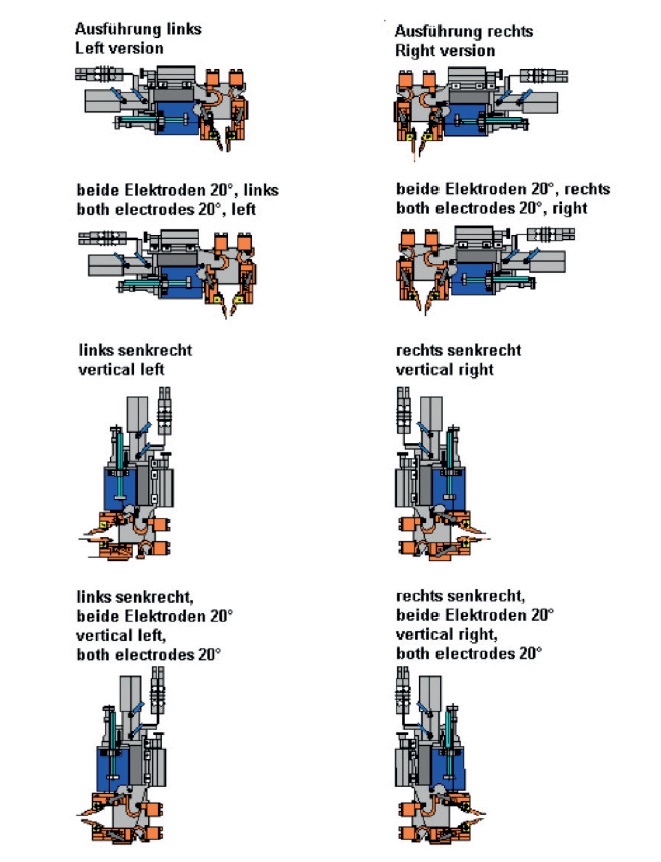

| Max. variations | Electrodes 0° (left), 20° (right), 20° (horizontal) and 20° (vertical) | Electrodes 0° (left), 20° (right), 20° (horizontal) and 20° (vertical) |

| Options | Add-on set – displacement sensor; support cylinder for programmable force setting; conversion kit to spring 0 (small force) with light current band | Add-on set – displacement sensor; support cylinder for programmable force setting; support cylinder for programmable force setting |

| Maximum rating | 5 kA (2 kA with light current band) | 5 kA (2 kA with light current band) |

| Closing stroke | Pneumatic | Pneumatic |

| Welding pressure | via pneumatic pre-tensioned spring | via pneumatic pre-tensioned spring |

| Weld force max | 15 to 150 N (option: spring 0 for 1.2 to 15 N) | 50 to 550 N |

| Air pressure supply | max 6 bar | max 6 bar |

| Weld force adjustment | adjustable screws on the scale housing or automatically with support cylinder | adjustable screws on the scale housing or automatically with support cylinder |

| Electrode shape | square electrodes 7.5 x 7.5 mm | square electrodes 7.5 x 7.5 mm |

| Electrode holder | quick change holder | quick change holder |

| Weld cables | 2x95mm², 700mm long | 4x95mm², 700mm long |

| Environment temp. | 0-40°C | 0-40°C |

| Legal approval | CE compliant | CE compliant |

| WEIGHT & DIMENSIONS | ||

| Weight | approx. 11 kg w/o secondary cable | approx. 15 kg w/o secondary cable |

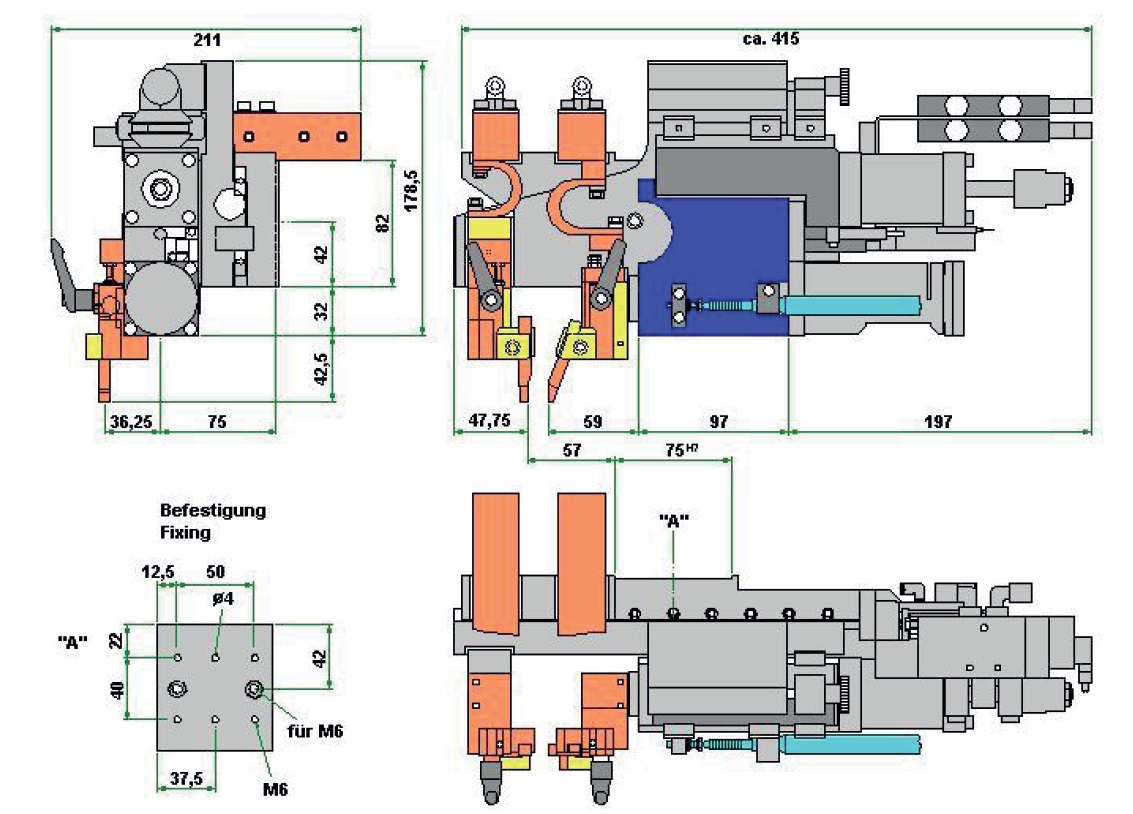

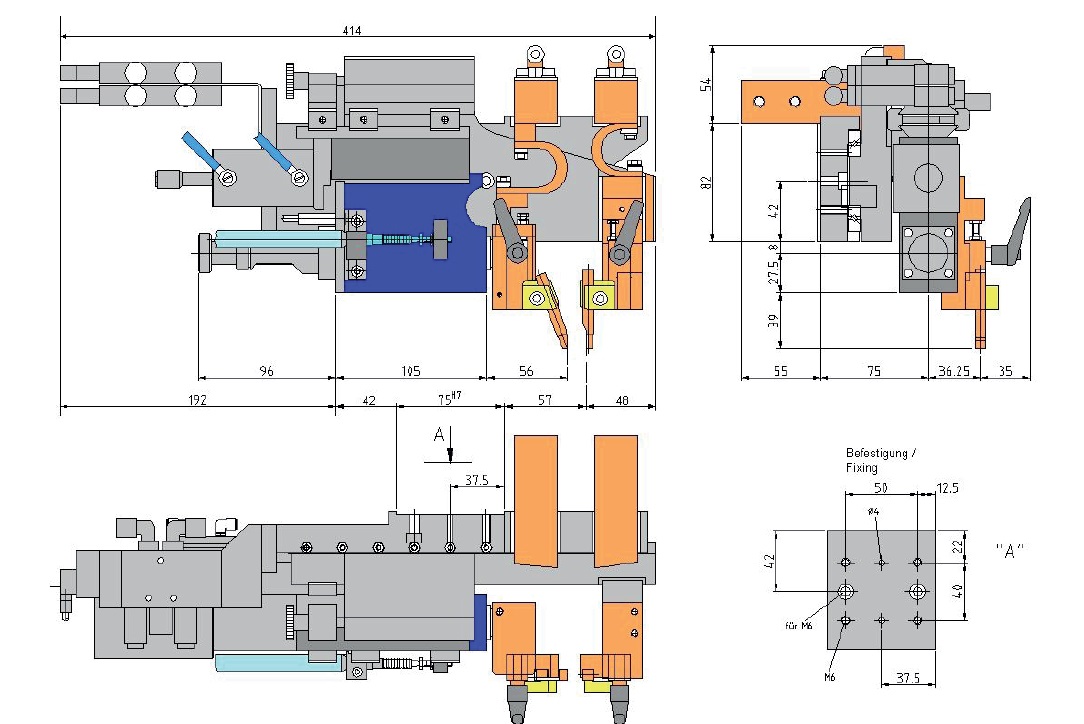

| Dimensions (LxHxD) | 211x414x201 mm | 221x415x211 mm |

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.