AMADA WELD TECH offers a full range of bonding heads which are available for the Hot Bar product line.

The bonding heads can be used for Hot Bar reflow soldering, ACF-Laminating, Heat Seal Bonding and Heat Staking. The bonding heads offer maximum productivity and consistent process control. The designs are modular, compact, rigid and easily adjustable.

You are here

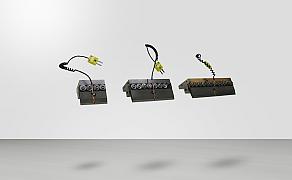

Hot Bar Modules

AMADA WELD TECH offers a full range of bonding heads that are available for the Hot Bar product line.

The bonding heads can be used for Hot bar reflow soldering, ACF-Laminating, Heat Seal Bonding and Heat Staking. The bonding heads offer maximum productivity and consistent process control. They have modular, compact and rigid designs and can be easily adjusted.

The interposer module is a reel-to-reel feeding module using a left and right sub-module which makes it independent of the Hot Bar length. The module holds a full spool of interposer on the left side and the feeder part on the right side collects the used Interposer material. An intelligent spring mechanism in the module prevents the interposer material from sticking to the Hot Bar after bonding.

The Thermode (Hot bar), which is at the heart of each bonding system, has been specially designed by AMADA WELD TECH for a range of applications.

UF-2000A / UF-4000A / UF-R4000A is a new power supply for Hot Bar Reflow Soldering, Heat-Sealing, ACF Laminating and Heat Staking technologies. It utilises pulsed heat technology to provide targeted heating and precision temperature control for a variety of components including flex circuits, ribbon cables, wires, SMT components, single or dual-sided edge connectors and thermo-compression bonding of gold ribbon.

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.